Voltec Cale Solutions

Nieuwe Eyckholt 282

6419 DJ Heerlen

info@voltec.nl

Nieuwe Eyckholt 282

6419 DJ Heerlen

info@voltec.nl

INSTRUMENTATION CABLE STANDARD EN50228-7

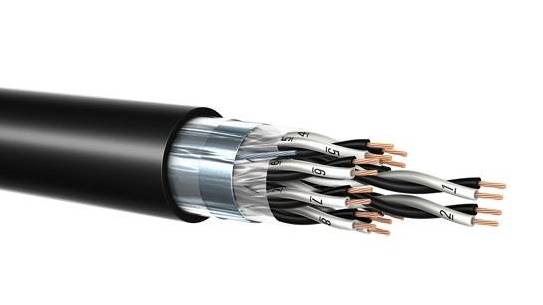

RE-2Y(St)Y

Single & Multi-Pair, PE-Insulation,

Collective Screen, PVC-Sheath

For transmission of analogue and digital signals in instrument and control systems; allowed for use in zone 1 and zone 2 group II classified areas (IEC60079-14); not allowed for direct connection to low impedance source, e.g. the public mains electricity supply. Recommended for indoor and outdoor installation, on racks, trays, in conduits, in dry and wet locations, not suitable for direct burial. (Please note the relevant legal / local installation requirements)

Properties

- CPR Eca

- Hydrocarbon and oil resistance

- Outdoor use

- UV-resistant

Construction & Technical data

|

Construction

|

||

|

Type

Conductor

Cross section

Insulation

Colour code

Wrapping

Collective screen

Outer sheath

Cable marking

|

RE

2Y

(St)

Y

|

instrumentation cable

plain annealed copper wire, solid class 1

1.02mmØ (AWG18), 1.38mmØ (1.5mm²)

polyethylene PE

black / white for pair, continuously numbered for multi-element

black / white / red for triple

at least 1 layer of plastic tape

aluminium / PETP tape over tinned copper drain wire, 0.5 mm² (7x0.3)

polyvinyl chloride PVC, black or blue for intrinsically safe systems

VOLTEC – RE-2YSt)Y – 300V – EN50288-7 IEC60332-3 IEC60332-1 EN50575:2014+A1:2016 CPR Class

|

|

Technical data

|

||

|

Fire properties

|

IEC 60332-1-2

|

|

|

CPR

|

EN 50575:2014+A1:2016

|

Eca

|

|

Limiting Oxygen Index (LOI)

|

ASTM D 2863

|

min. 30%

|

|

Smoke Density

|

IEC 61034

|

Light transmittance ≥ 20%

|

|

Amount of halogen acid gas

|

IEC 60754-1

|

HCI ≤ 22%

|

|

Acidity (ph value) and conductivity

|

IEC 60754-2

|

|

|

Low Voltage Directive (LVD)

|

2014/35/EU

|

|

|

Complies with Sitech standard

|

PD 4.7.3-2.4.1.2 & PD 4.7.3-2.4.1.3 for DI/DO signals (1.38mmØ)

PD 4.7.3-2.3.1.2 & PD 4.7.3-2.3.1.3 for high-level signals (1.02mmØ)

|

|

|

Electrical and mechanical properties

|

|||||||

|

Cross section acc. IEC 60228

|

1.02

|

1.38

|

nom. mmØ

|

||||

|

DC resistance @20°C acc. EN 50289-1-2

|

21.2

|

12.3

|

max Ω/km

|

||||

|

Insulation acc. EN 50289-1

|

1.8

|

2.0

|

nom. mmØ

|

||||

|

Mutual Capacitance acc. EN 50289-1-5

|

< 150

|

< 150

|

nF/km

|

||||

|

L/R ratio acc. EN 50289-1-2/12

|

<25

|

<40

|

μH/Ω

|

||||

|

Insulation resistance

|

1000

|

min MΩ*km

|

|||||

|

Dielectric test core/core

|

1000

|

Vac@1min

|

|||||

|

Dielectric test core/screen

|

500

|

Vac@1min

|

|||||

|

Operating voltage

|

300

|

V

|

|||||

|

Temperature range

|

|||||||

|

- during installation

|

-5 up to +65

|

°C

|

|||||

|

- during operation

|

-20 up to +80

|

°C

|

|||||

|

Min. bending radius

|

8 x cable diameter

|

||||||

The technical information and dimensions mentioned above may vary from the actual product. Always verify the issued information before placing an order. Please note that specifications are subject to change without prior notice.

Cable sizes

|

Black

Non-Ex-i |

|

Blue

Ex-i / intrinsically safe |

|

Range

|

Diameter

± Ømm

|

Weight

± kg/km

|

Part no.

Black |

Part no.

Blue |

|---|---|---|---|---|

|

1x2x1.02

|

8.0

|

70

|

6020 0202

|

6020 0203

|

|

2x2x1.02

|

9.8

|

110

|

6020 0402

|

6020 0403

|

|

4x2x1.02

|

11.1

|

155

|

6020 0802

|

6020 0803

|

|

12x2x1.02

|

15.9

|

335

|

6020 2402

|

6020 2403

|

|

16x2x1.02

|

17.8

|

425

|

6020 3202

|

6020 3203

|

|

24x2x1.02

|

21.4

|

610

|

6020 4802

|

6020 4803

|

|

Range

|

Diameter

± Ømm

|

Weight

± kg/km

|

Part no.

Black |

Part no.

Blue |

|---|---|---|---|---|

|

1x2x1.38

|

9.1

|

100

|

6025 0202

|

6025 0203

|

|

2x2x1.38

|

11.8

|

170

|

6025 0402

|

6025 0403

|

|

12x2x1.38

|

20.1

|

555

|

6025 2402

|

6025 2403

|

|

24x2x1.38

|

27.6

|

1040

|

6025 4802

|

6025 4803

|

|

Range

|

Diameter

± Ømm

|

Weight

± kg/km

|

Part no.

Black |

Part no.

Blue |

|---|---|---|---|---|

|

1x3x1.02

|

8.3

|

85

|

6021 0302

|

6021 0303

|

|

2x3x1.02

|

10.7

|

135

|

6021 0602

|

6021 0603

|

|

12x3x1.02

|

18.0

|

505

|

6021 3602

|

6021 3603

|

|

24x3x1.02

|

25.0

|

945

|

6021 7202

|

6021 7203

|

|

Range

|

Diameter

± Ømm |

Weight

± kg/km |

Part no.

Black |

Part no.

Blue |

|

1x2x1.02

|

8.0

|

70

|

6020 0202

|

6020 0203

|

|

2x2x1.02

|

9.8

|

110

|

6020 0402

|

6020 0403

|

|

4x2x1.02

|

11.1

|

155

|

6020 0802

|

6020 0803

|

|

12x2x1.02

|

15.9

|

335

|

6020 2402

|

6020 2403

|

|

16x2x1.02

|

17.8

|

425

|

6020 3202

|

6020 3203

|

|

24x2x1.02

|

21.4

|

610

|

6020 4802

|

6020 4803

|